Pressurized Structures and Aerospace Tankage

ASME Certified Pressure Vessels

ASME Section VIII, Division I and Division II

Let us add ASME "Design by Analysis" capabilities to your firm.

While the majority of ASME pressure vessels fall into the "Design by Rules" certification category, we can help your firm go after more lucrative, highly engineered pressure vessels that fall under the purview of ASME "Design by Analysis", including Pressure Vessels for Human Occupancy (PVHO). We can analyze your vessel to guarantee against failure by plastic collapse, failure by buckling, failure by cyclic fatigue, and other criteria as applicable. These vessels can be produced under either a Division I or Division II stamp, and can open up a whole new marketplace for your company.HazMat Transport

Tip and Spill Resistant

Pressurized transportation of hazardous material often requires third-party certification.

Oil Seperators

Industrial Equipment

We can help design industrial tankage such as oil separators and air storage equipment.

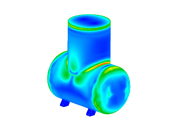

Hyperbaric / PVHO

Medical, Mining, and Diving

Engineering expertise for Pressure Vessels for Human Occupancy.

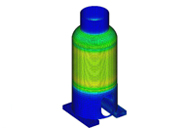

Case Study

Tunnel Boring Machine Hyperbaric Chamber

Structure, Incorporated was retained in order to perform the sizing and certification analysis for this large hyperbaric chamber. The chamber houses up to four operators of a large-scale tunnel boring machine and can be pressurized in up to seven different loading scenarios. The vessel was analyzed according to ASME Section VIII Division II Design by Analysis, but certified under Division I material allowables. Due to the large number of subcomponents and the numerous pressurization scenarios, the certification report for this vessel was over 400 pages.

Finite Element Model